In the quest for sustainable manufacturing, researchers are turning their attention to the often-overlooked end-of-life cycle of 3D printed materials. A recent study published in the journal *Macromolecular Materials and Engineering* (which translates to *Macromolecular Engineering Materials*) sheds light on the recycling potential of polyethylene terephthalate glycol (PETG), a thermoplastic commonly used in material extrusion additive manufacturing (MEX), also known as fused deposition modeling (FDM) or fused filament fabrication (FFF). The research, led by Sierra F. Yost from the Department of Chemical Engineering at The Pennsylvania State University, explores how the composition of PETG affects its degradation during recycling, offering insights that could revolutionize the circular economy in the construction and energy sectors.

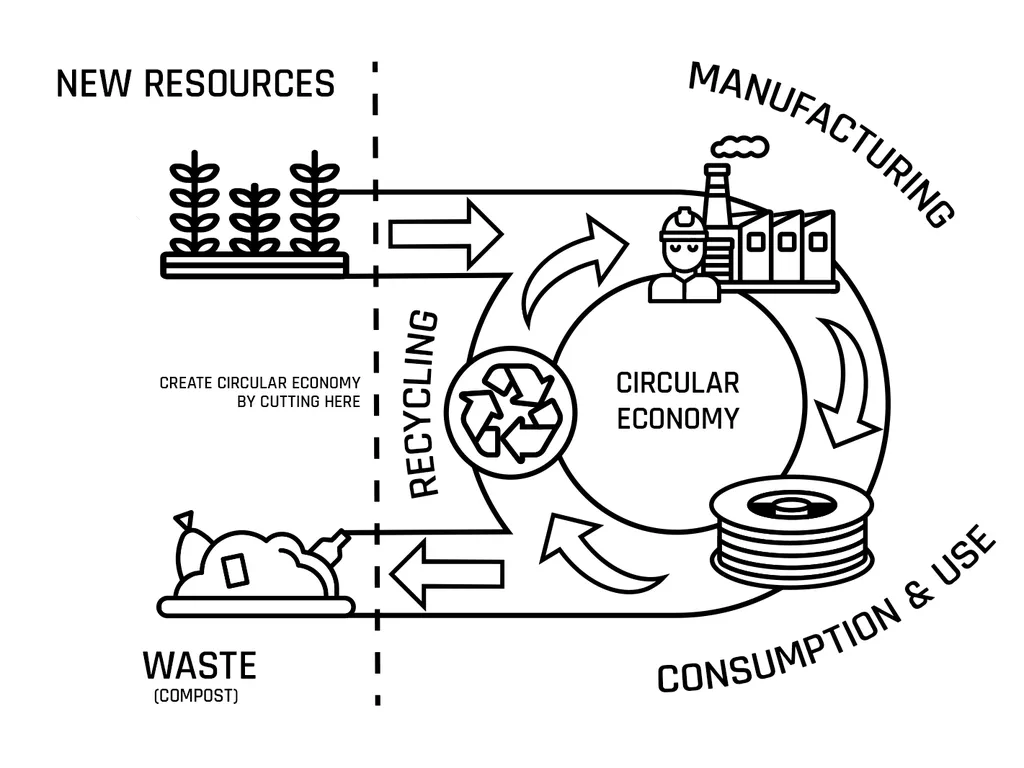

PETG is a popular choice for 3D printing due to its ease of use and versatility. However, its compatibility with existing recycling infrastructures has been a significant challenge. Unlike its counterpart, polyethylene terephthalate (PET), PETG contains a comonomer called cyclohexane dimethanol (CHDM), which can compromise the integrity of PET recycling streams. This incompatibility has led to a linear, non-circular end-of-life disposition for PETG, undermining the environmental benefits of additive manufacturing.

Yost and her team set out to investigate the circular recycling of PETG within the MEX ecosystem. They demonstrated that the reduction in the viscosity of PETG through multiple cycles of printing, testing, and reprocessing into filament is dependent on the sourcing of the material but not directly correlated with the CHDM content or molar mass. This finding is crucial for understanding how different commercial sources of PETG behave during recycling.

The study also revealed that the elastic modulus and tensile strength of printed PETG are not significantly impacted by recycling over five prints. However, the ductility of the printed PETG shows a more complex behavior. For PETG with the lowest CHDM content, ductility decreases after just one recycling cycle. In contrast, for PETG with higher CHDM content, ductility first increases and then decreases through multiple reprocess cycles.

“This research illustrates that circular recycling through MEX may increase the number of cycles possible without significant degradation in part stiffness and strength when compared with mechanical recycling using traditional manufacturing methods,” Yost explained. “This could have profound implications for the energy sector, where the durability and longevity of components are paramount.”

The findings suggest that by optimizing the composition and recycling processes, it may be possible to extend the life cycle of PETG materials significantly. This could lead to more sustainable manufacturing practices in industries that rely heavily on 3D printing, such as construction and energy. As the push for a circular economy gains momentum, understanding the nuances of material recycling becomes increasingly important.

Yost’s research not only highlights the potential for improving the sustainability of additive manufacturing but also underscores the need for further investigation into the behavior of different thermoplastic materials during recycling. As the energy sector continues to explore the use of 3D printing for creating complex and durable components, the insights from this study could pave the way for more efficient and environmentally friendly manufacturing processes.

In the broader context, this research could influence the development of new recycling technologies and standards tailored to the unique requirements of additive manufacturing. By addressing the challenges associated with PETG recycling, the construction and energy sectors can move closer to achieving their sustainability goals, reducing waste, and minimizing their environmental footprint.

As the industry continues to evolve, the findings from Yost’s study serve as a reminder that innovation in material science and recycling technologies is key to unlocking the full potential of additive manufacturing. By embracing a circular economy approach, the construction and energy sectors can not only enhance their operational efficiency but also contribute to a more sustainable future.