In a groundbreaking development that could revolutionize the way we interact with machines and monitor our health, researchers have drawn inspiration from an unlikely source: the humble sea urchin. Weihua Gao, a researcher at the State Key Laboratory of Crane Technology, Yanshan University, and his team have developed a novel tactile sensor that mimics the unique motion of the sea urchin’s tooth plate, potentially opening up new avenues in the energy sector and beyond.

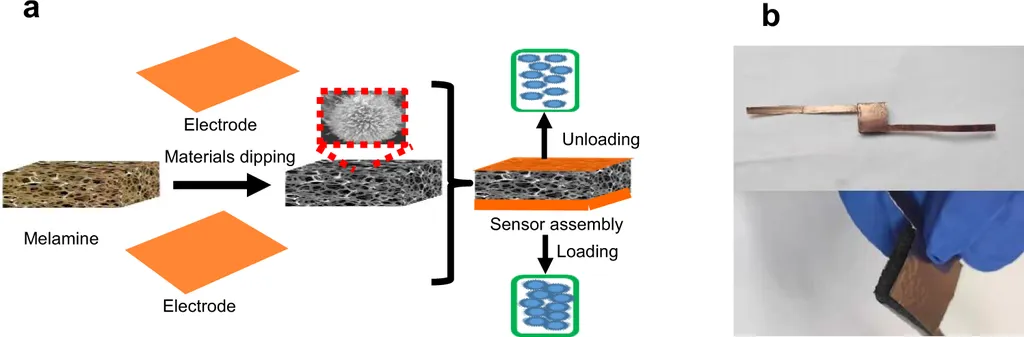

The sensor, dubbed the tooth plate flexible tactile sensor (TPFTS), integrates a bio-inspired elastomeric structure with conductive foam, achieving a remarkable level of stress-strain tunability. This innovation addresses a longstanding challenge in tactile sensor technology: the struggle to control force-electric response and viscoelastic hysteresis, which have traditionally limited the linear range and response speed of these devices.

“Our sensor achieves linear regulation of force-electric response, with a wide linear range of 80-606 kPa and an impressive R-squared value of 0.988,” Gao explains. This means the sensor can provide highly accurate and consistent readings across a broad spectrum of pressures, making it ideal for applications that require precise force measurement.

But the benefits don’t stop there. The TPFTS also boasts a rapid response and recovery time of just 29/24 milliseconds, respectively, and excellent stability, maintaining its performance even after over 20,000 cycles of use. Perhaps most impressively, the sensor can continue to function effectively even with severe physical damage, with signal stability remaining above 95% even with an 8% volume loss.

So, what does this mean for the energy sector? The potential applications are vast. For instance, the TPFTS could be used to enhance the safety and efficiency of robotic systems in hazardous environments, such as offshore oil rigs or nuclear power plants. By providing real-time, high-fidelity feedback, the sensor could help prevent accidents and improve the overall performance of these systems.

Moreover, the sensor’s robustness and durability make it well-suited for use in wearable technology, which could be a game-changer for health monitoring in high-risk occupations within the energy sector. Workers could wear these sensors to monitor their physical exertion and detect early signs of fatigue or injury, allowing for timely intervention and prevention of more serious health issues.

The research, published in the journal *npj Flexible Electronics* (translated to English as “npj Flexible Electronics”), represents a significant step forward in the field of tactile sensor technology. As we look to the future, the TPFTS could pave the way for a new generation of smart, responsive, and resilient devices that can operate effectively in even the most challenging environments.

In the words of Gao, “This research not only advances our understanding of bio-inspired design but also opens up exciting new possibilities for the application of tactile sensors in various fields.” As we continue to explore and develop these technologies, we can expect to see even more innovative solutions that push the boundaries of what’s possible in the energy sector and beyond.