In a groundbreaking development poised to revolutionize the energy sector, researchers have unveiled a novel approach to creating highly foldable and leakage-free electrodes using ultrathin liquid metal micromeshes. This innovation, published in the journal *npj Flexible Electronics* (translated to English as “Flexible Electronics”), promises to address long-standing challenges in stretchable electronics, offering robust solutions for flexible energy harvesting, storage, and transmission.

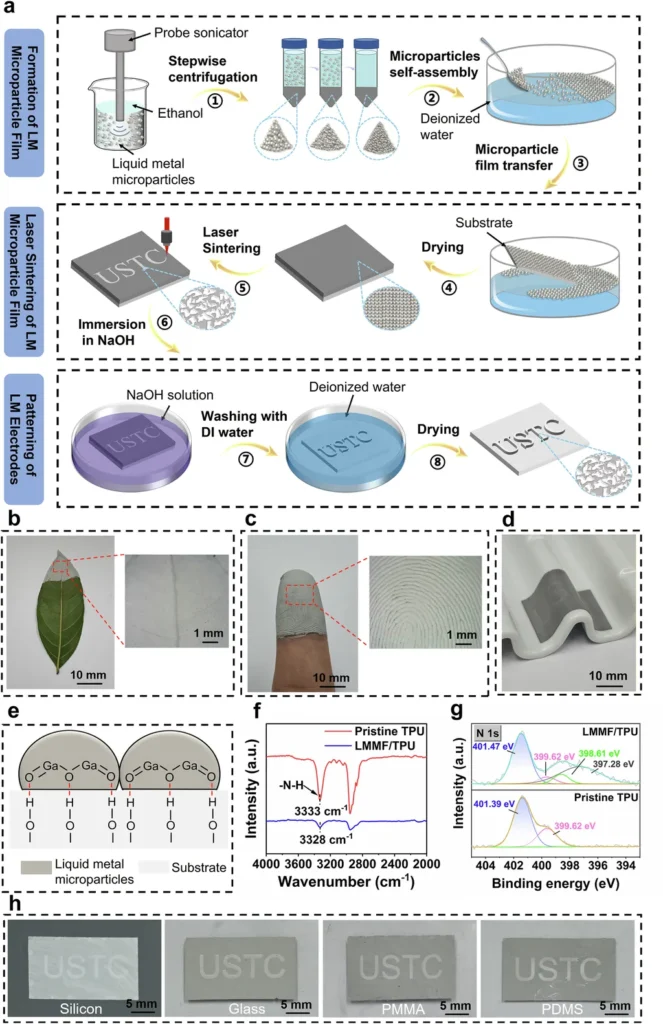

At the heart of this research is the use of gallium-based liquid metals, known for their potential in flexible electronics but historically plagued by issues of fluidity and structural confinement. The lead author, Xin Yang from the Department of Precision Machinery and Precision Instrumentation at the University of Science and Technology of China, and his team have developed a method to fabricate ultrathin liquid metal micromesh electrodes through interfacial self-assembly of microparticles and subsequent laser sintering. “The key breakthrough here is the unique micromesh architecture that not only disperses strain and alleviates stress concentration but also confines the liquid metal within defined pathways, preventing leakage and ensuring structural integrity under extreme deformation,” Yang explained.

The electrodes, with a minimum thickness of just 317 nanometers, exhibit remarkable stretchability, capable of enduring up to 1200% strain while maintaining stable performance. They have demonstrated exceptional mechanical robustness, enduring 10,000 folding cycles at a 70-micrometer bending radius without compromising functionality. This durability is crucial for applications in flexible and wearable electronics, where devices must withstand repeated deformation and harsh conditions.

One of the most compelling aspects of this research is the electrodes’ ability to maintain excellent electrical stability. Even at 300% strain, the resistance change (R/R₀) is minimal, at just 1.66, ensuring reliable performance in dynamic environments. Additionally, the micromesh structure endows the electrodes with translucency, opening up new possibilities for integrating them into transparent and flexible devices.

The commercial implications for the energy sector are substantial. Flexible electrodes are essential for developing wearable energy harvesters, such as solar cells and thermoelectric devices, as well as flexible batteries and supercapacitors. These advancements could lead to more efficient and adaptable energy solutions, enabling the integration of renewable energy technologies into everyday applications.

Moreover, the electrodes’ ability to facilitate wireless power transfer and angular sensing further expands their potential applications. “This technology could be a game-changer for industries looking to incorporate flexible and durable electronics into their products,” Yang noted. “From medical devices to smart fabrics, the possibilities are vast.”

As the world continues to seek innovative solutions for sustainable energy and advanced electronics, this research represents a significant step forward. The development of highly foldable and leakage-free electrodes using ultrathin liquid metal micromeshes not only addresses critical challenges in material science but also paves the way for future advancements in flexible and wearable technologies. With the publication in *npj Flexible Electronics*, this research is set to inspire further exploration and collaboration, driving the energy sector toward a more flexible and resilient future.