In the high-stakes world of nuclear industry equipment, where failure is not an option, a groundbreaking study is shedding new light on the behavior of composite materials under extreme conditions. Researchers at the Harbin Institute of Technology, led by Jia Liwei, have developed a novel approach to understanding how composite thin-walled cylinders, used in specialized nuclear equipment, withstand long-term high-stress operations.

The study, published in *Science and Engineering of Composite Materials* (translated from Chinese as *复合材料科学与工程*), focuses on the meso-scale damage behavior of these composite structures, providing insights that could significantly impact the energy sector. “By looking at the material behavior at a meso-scale level, we can gain a deeper understanding of how these composites fail under different loading conditions,” Liwei explains.

The research team employed the cell element method, a meso-scale approach, to embed into finite element models and calculate the meso-scale stress field of the material. This allowed them to construct a macro-meso dual-scale damage analysis model, which was verified through experiments. The model considers both interlayer and intralayer damage, providing a comprehensive view of the material’s behavior.

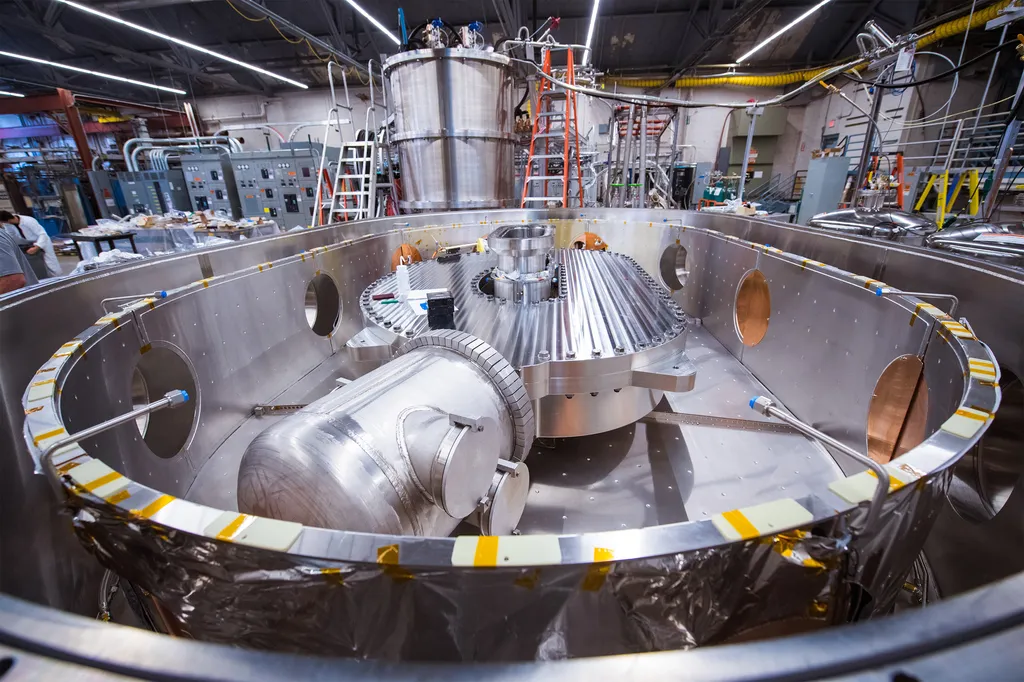

The findings are particularly relevant for the nuclear industry, where composite rotating drums are subjected to high stress over long periods. The study identified two dominant loading conditions: compressive instability failure and bending failure. “The transverse stress of the matrix in the 31° angled layer leads to compressive instability failure at the end of the cylindrical shell,” Liwei notes. Additionally, the bending failure of the 50° angled layer is caused by axial bending stress concentration, which induces radial cracks in the circumferential layer.

Understanding these failure mechanisms and damage evolution laws can help in designing more robust and reliable composite structures for the energy sector. This research could lead to the development of safer and more efficient nuclear equipment, ultimately contributing to the advancement of nuclear energy technology.

The implications of this study extend beyond the nuclear industry. The insights gained from this research can be applied to other sectors where composite materials are used under high-stress conditions, such as aerospace and automotive industries. By improving the understanding of composite material behavior, this research paves the way for innovative designs and applications in various fields.

As the energy sector continues to evolve, the need for advanced materials that can withstand extreme conditions becomes increasingly important. This study by Liwei and his team at the Harbin Institute of Technology represents a significant step forward in our understanding of composite materials, with potential benefits for the energy sector and beyond.