In a groundbreaking development for the energy sector, researchers have pioneered a rapid, high-performance method for protecting Inconel 718 (IN718) superalloys, a material widely used in extreme environments such as gas turbines and nuclear reactors. The study, led by Aptullah Karakaş from Istanbul Technical University and Repkon Machine and Tool Industry, introduces a novel technique called Pack Induction Aluminizing (PIA), which significantly reduces the time required to apply protective aluminide coatings compared to traditional methods.

Traditionally, aluminizing IN718 involves a time-consuming process that can take several hours in a furnace. However, Karakaş and his team have demonstrated that the PIA process can achieve the same results in just a few tens of minutes. “The key advantage of our method is the dramatic reduction in processing time,” Karakaş explains. “This not only increases efficiency but also makes the process more economically viable for industrial applications.”

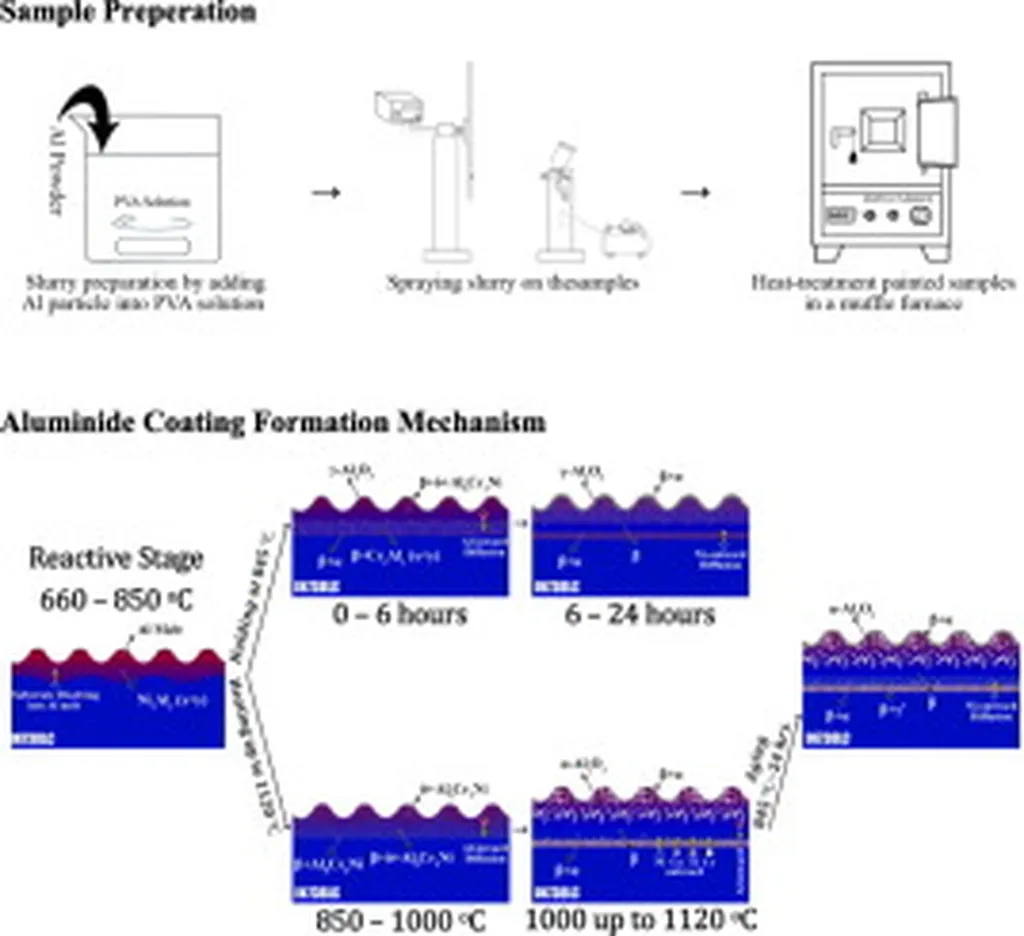

The researchers applied the PIA process to IN718 superalloys produced by Cold Spray Additive Manufacturing (CSAM), a technique that builds up materials layer by layer. By increasing the processing time from 5 minutes to 10 minutes, they observed a substantial increase in coating thickness, from approximately 10 micrometers to 19 micrometers. This resulted in a double-layered aluminide coating, characterized by an outer layer of Ni(Fe,Cr)Al₃ and an inner layer of Ni₂(Fe,Cr)Al₃, typical of high-activity aluminizing processes.

The study, published in *Materials Research Express* (which translates to *Materials Research Express* in English), also revealed significant improvements in tribological properties. The friction coefficient slightly decreased, wear resistance increased, and wear track depth decreased by approximately 80% compared to the uncoated alloy. “These findings demonstrate that the PIA method is a highly effective and rapid technique for producing protective, high-performance aluminide coatings on IN718 superalloy,” Karakaş notes.

The implications for the energy sector are profound. IN718 superalloys are critical components in high-temperature and high-stress environments, such as gas turbines and nuclear reactors. The ability to rapidly apply protective coatings not only enhances the durability and performance of these components but also reduces downtime and maintenance costs. “This research opens up new possibilities for improving the reliability and efficiency of energy systems,” Karakaş adds.

As the energy sector continues to demand materials that can withstand extreme conditions, the PIA process offers a promising solution. By reducing processing time and enhancing performance, this innovative method could shape the future of material science and engineering, paving the way for more robust and efficient energy technologies.