In the quest to enhance the water resistance of construction materials and promote sustainable waste utilization, researchers have made a significant stride by incorporating red mud (RM) into phosphogypsum-based composites. This innovative approach, detailed in a recent study published in *Case Studies in Construction Materials* (translated as “典型案例:建筑材料”), could have profound implications for the energy sector and beyond.

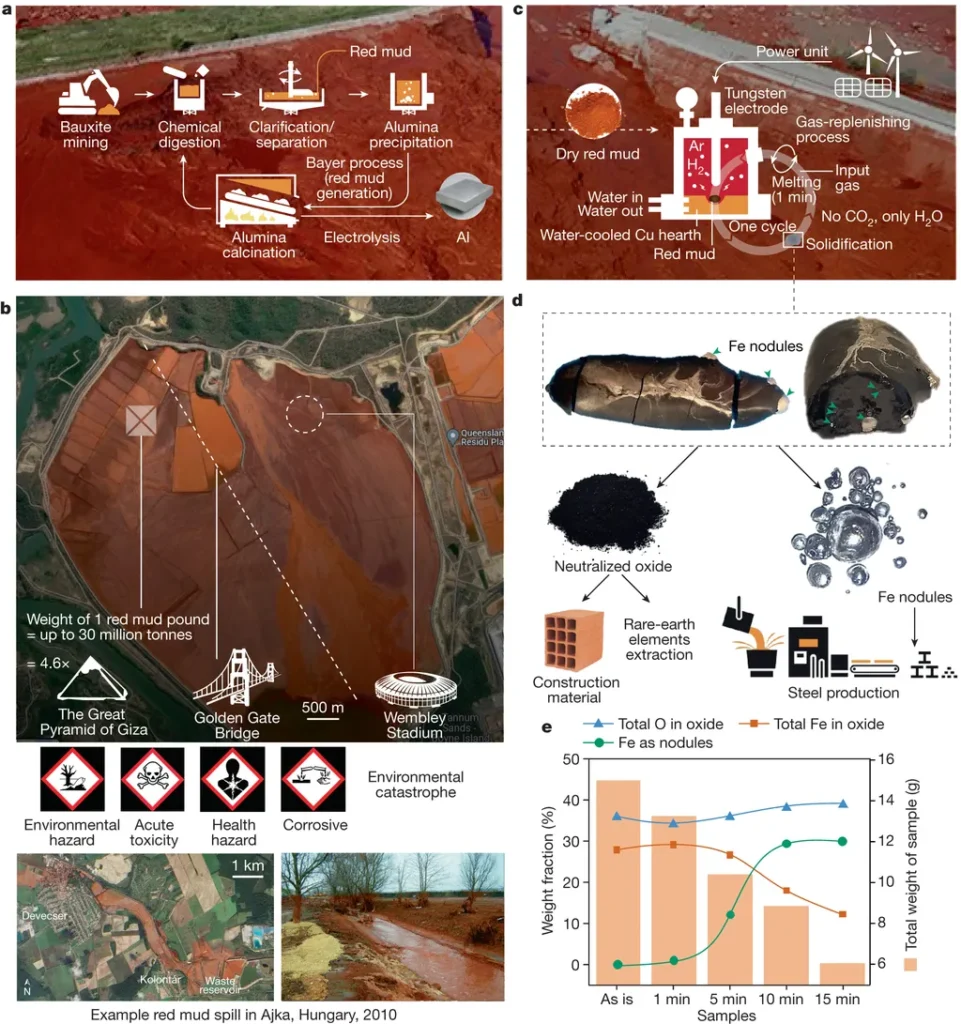

The study, led by Jiazhe Chen from the Research Center of Spatial Structure at Guizhou University in China, explores the synergistic effects of red mud and calcium oxide (CaO) on the performance of phosphogypsum-based cementitious materials. Phosphogypsum, a byproduct of phosphoric acid production, has long been underutilized due to its poor water resistance. Red mud, a waste product from aluminum production, presents similar challenges.

Chen and his team discovered that by adding CaO as an activator, they could significantly enhance the properties of these materials. “The key was to find the right balance,” Chen explained. “We found that a mixture containing 10% red mud and 2% CaO achieved optimal performance, with a 28-day compressive strength of 39.27 MPa and a softening coefficient of 0.85.”

These improvements represent a notable enhancement compared to mixtures without CaO, with increases of 4.3% in compressive strength, 13.8% in flexural strength, and 11.8% in the softening coefficient. The researchers attributed this performance boost to the activation of red mud by CaO, which promotes the release of aluminum ions. These ions react with other compounds to form ettringite (AFt), a mineral that fills pores and creates a dense microstructure, enhancing water resistance.

However, the study also revealed that excess CaO can have detrimental effects. A high CaO content of 5% resulted in the lowest softening coefficient, as it led to an abundance of calcium hydroxide and promoted carbonation reactions, compromising the material’s performance.

The findings of this research could have significant commercial impacts, particularly in the energy sector. Phosphogypsum is a byproduct of fertilizer production, and finding sustainable uses for it could benefit the agricultural industry as well. Additionally, the utilization of red mud, a waste product from aluminum production, aligns with the growing emphasis on circular economy principles.

As the construction industry continues to seek sustainable and high-performance materials, this research offers a promising avenue for exploration. By leveraging the synergistic effects of red mud and CaO, developers can create more durable and environmentally friendly construction materials.

“This study opens up new possibilities for the utilization of industrial byproducts in construction,” Chen noted. “It’s a step towards a more sustainable future, where waste materials are transformed into valuable resources.”

The research not only advances our understanding of phosphogypsum-based materials but also underscores the importance of interdisciplinary collaboration in driving innovation. As the energy sector continues to evolve, such advancements will be crucial in shaping a more sustainable and efficient future.