In the heart of Hong Kong, researchers are tackling a challenge as hard as diamond itself. Song Yuan, a leading figure from the State Key Laboratory of Ultra-precision Machining Technology at The Hong Kong Polytechnic University, has just published a groundbreaking review in the *International Journal of Extreme Manufacturing* (translated as “Extreme Manufacturing International”). The journal, known for its cutting-edge research, has spotlighted Yuan’s work on polishing diamonds to an atomic scale without causing damage. This isn’t just about making diamonds shine brighter; it’s about unlocking their full potential in extreme environments, particularly in the energy sector.

Diamonds are renowned for their resilience in high temperatures, high pressures, and corrosive conditions. These properties make them invaluable in quantum devices, high-power optical systems, and ultra-high-frequency electronic devices. However, their brittleness and susceptibility to damage during processing have limited their practical applications. Yuan’s research addresses this challenge head-on, focusing on achieving ultra-smooth, damage-free surfaces with nanometer-scale roughness and sub-micrometer form accuracy.

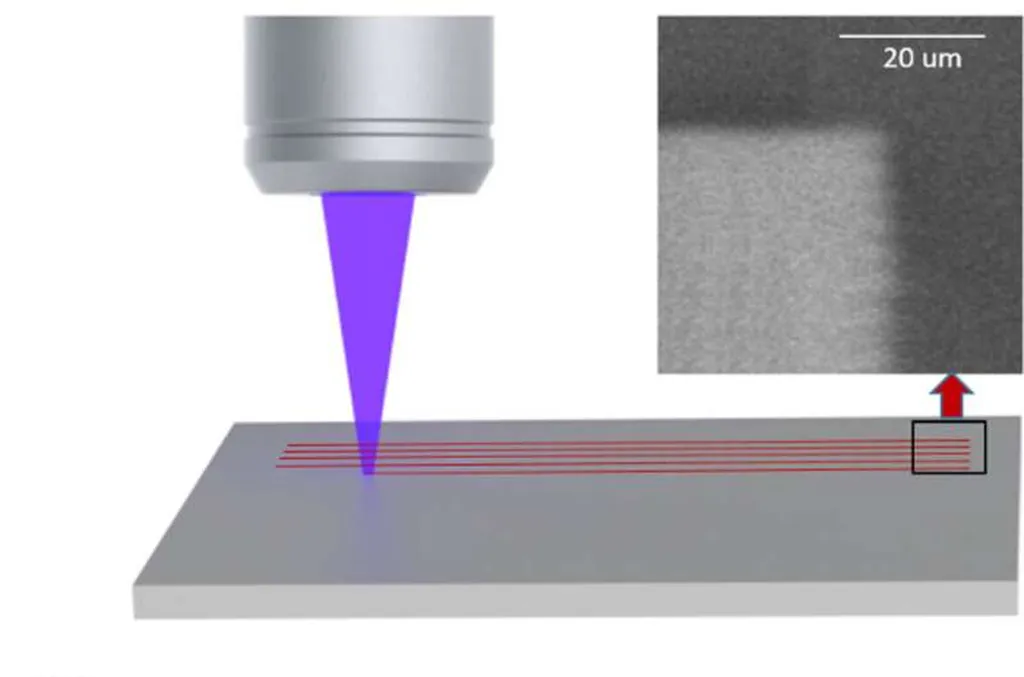

The review systematically examines various polishing technologies, from laser polishing to chemical mechanical polishing, and even plasma-assisted polishing. Yuan and his team have identified four fundamental material removal mechanisms: microfracture, graphitization, oxidation, physical sputtering, and chemical etching. By combining these mechanisms, they’ve developed hybrid, multi-physics polishing strategies that significantly improve material removal rates and surface quality.

“Our goal is to achieve atomic-level surface integrity,” Yuan explains. “This involves balancing the material removal rate and surface quality, which is crucial for the diamond’s performance in extreme conditions.”

The implications for the energy sector are substantial. Diamonds polished to such precision could revolutionize high-power optical systems and electronic devices used in energy generation and transmission. They could also enhance the performance of quantum devices, which are critical for advancing renewable energy technologies.

Looking ahead, Yuan’s research outlines future directions, emphasizing innovations in multi-physics coupling mechanisms and intelligent control of atomic-scale manufacturing processes. This work provides a theoretical foundation and technical pathways to overcome the coupled challenges of atomic precision, efficiency, and extreme service conditions.

As the energy sector continues to evolve, the need for materials that can withstand extreme conditions grows ever more pressing. Yuan’s research offers a promising solution, paving the way for advancements in energy technologies and beyond. With the publication of this review, the scientific community is one step closer to unlocking the full potential of diamonds in the energy sector.