In the quest to enhance energy efficiency in buildings, researchers have turned to an unlikely ally: rubber. A recent study published in the journal *Express Letters in Polymer Science* (eXPRESS Polymer Letters) has uncovered significant insights into how the curing process and the amount of blowing agent can influence the properties of ethylene-propylene-diene monomer (EPDM) foam, a material with promising applications in thermal insulation.

Led by Kazem Honarkar, the research delves into the intricate world of polymer foams, exploring how different sulfur curing systems and varying levels of azodicarbonamide (ADC) blowing agent affect the cellular structure, mechanical strength, and thermal conductivity of EPDM foam. The study considered three types of sulfur curing systems—efficient, semi-efficient, and conventional—and three levels of ADC, resulting in nine distinct EPDM foam formulations.

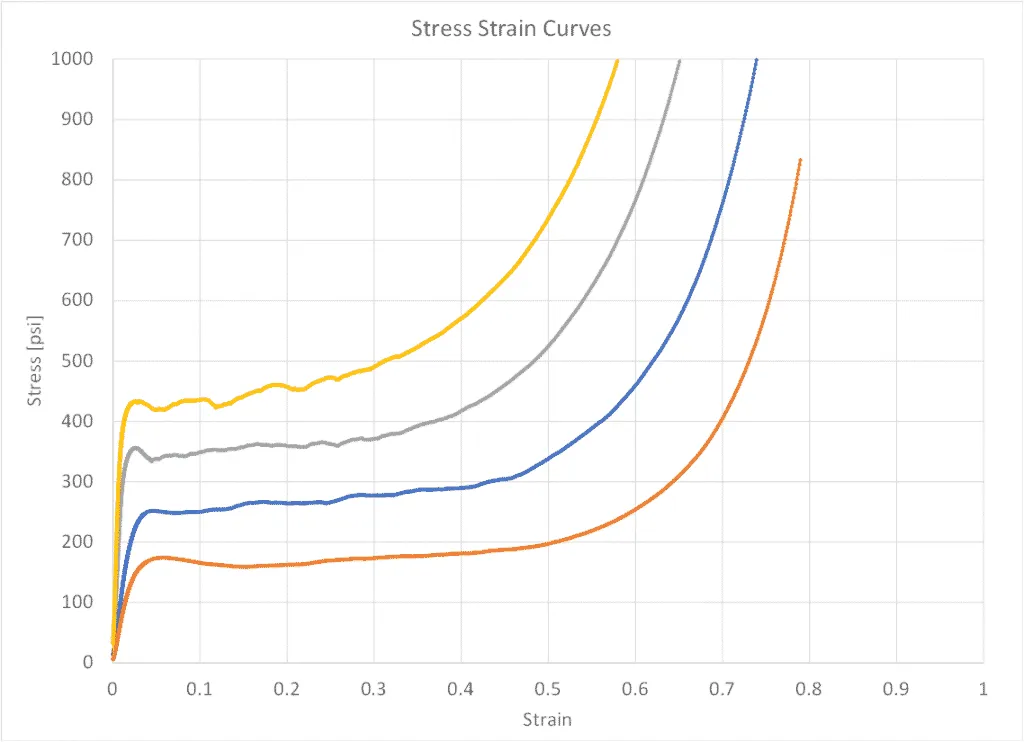

The findings are compelling. The type of curing system and the amount of ADC significantly impact the foam’s cell morphology, density, and mechanical properties. “We observed that a decrease in density leads to reduced mechanical properties,” Honarkar noted. This is a crucial insight for manufacturers aiming to balance the foam’s lightweight nature with its structural integrity.

But the real game-changer lies in the potential energy savings. The study employed DesignBuilder software to model the thermal insulation performance of the foams in building applications. The results were striking: using EPDM foams as thermal insulation could reduce the energy consumption of heating, ventilation, and air conditioning (HVAC) systems by up to 20%.

This research opens up new avenues for the energy sector. As buildings account for a significant portion of global energy consumption, innovative insulation materials like EPDM foam could play a pivotal role in reducing energy demand. The study’s findings could influence future developments in polymer foam technology, driving the creation of more efficient and sustainable insulation solutions.

Honarkar’s work underscores the importance of understanding the fundamental properties of materials. By fine-tuning the curing process and blowing agent content, manufacturers can tailor EPDM foams to meet specific performance requirements, paving the way for more energy-efficient buildings.

As the world grapples with the challenges of climate change and energy conservation, such advancements in material science offer a glimmer of hope. The research published in *Express Letters in Polymer Science* (eXPRESS Polymer Letters) not only sheds light on the potential of EPDM foams but also highlights the broader impact of materials research on the energy sector.