In the quest for sustainable energy solutions, a team of researchers from the School of Materials Science and Engineering at Shenyang Jianzhu University in China has made a significant stride. Led by Kaiwen Fan, the team has explored the potential of cement-based thermoelectric materials to harness waste heat from building surfaces, offering a promising avenue for green energy recovery. Their findings, published in the journal *Materials Research Express* (translated as “Materials Research Express”), could reshape the energy landscape by integrating renewable energy solutions into everyday construction materials.

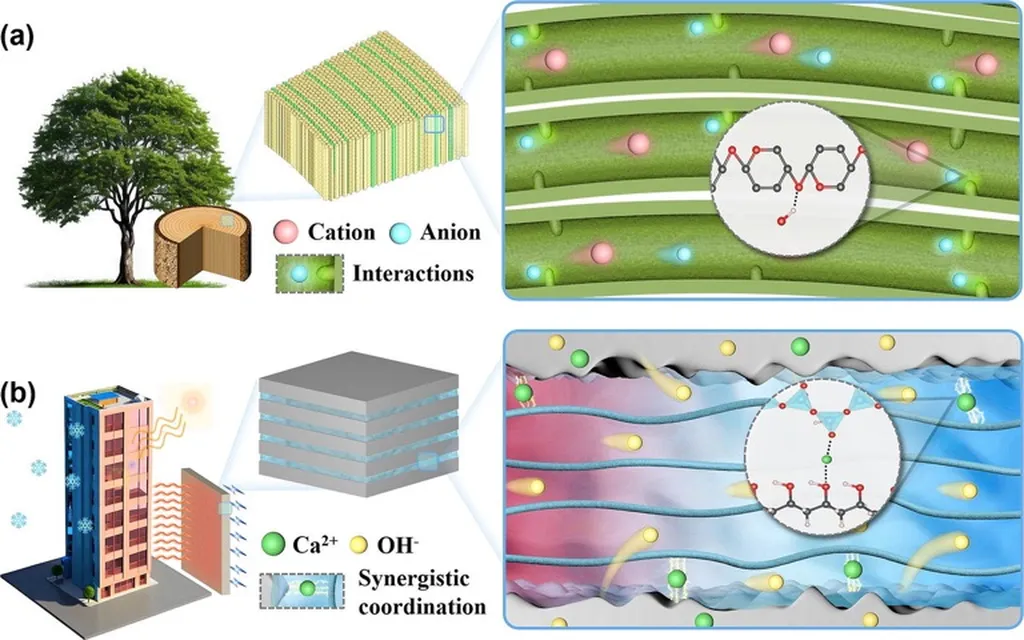

The study focused on incorporating two types of functional fillers—graphene (Gr) and carbon black (CB)—into cement composites. These fillers were added at varying concentrations to evaluate their impact on the material’s compressive strength, electrical resistivity, and thermoelectric properties. The results were compelling. “The highest percentage increase in compressive strength was achieved at a functional filler content of 0.4 vol%,” Fan explained. This enhancement in mechanical properties is crucial for the structural integrity of buildings, making the material not only energy-efficient but also robust.

One of the most intriguing aspects of the research was the investigation into the electrical resistivity of the composites. The team found that resistivity decreased as the temperature increased, a phenomenon that could be harnessed to convert waste heat into electrical energy. “Higher filler content facilitated the formation of conductive networks, leading to reduced resistivity,” Fan noted. This finding is particularly significant for the energy sector, as it opens up new possibilities for integrating thermoelectric materials into building surfaces to capture and utilize environmental heat.

The study also delved into the Seebeck effect, which measures the material’s ability to convert temperature differences into electrical voltage. The researchers observed that graphene, at a concentration of 0.6 vol%, exhibited the lowest resistivity at 100 °C and demonstrated enhanced thermoelectric performance. This suggests that graphene could be a key player in the development of advanced thermoelectric materials for energy recovery applications.

Scanning electron microscopy (SEM) revealed that the distribution and interconnection of the functional fillers within the cement matrix played a pivotal role in determining the material’s mechanical, temperature-sensitive, and thermoelectric properties. This insight could guide future research in optimizing the performance of cement-based thermoelectric materials.

The implications of this research are far-reaching. By integrating thermoelectric materials into building surfaces, it is possible to convert waste heat into usable electrical energy, contributing to a more sustainable and low-carbon future. “This study provides a foundation for further exploration and development of cement-based thermoelectric materials,” Fan said. “It offers a promising avenue for energy recovery and could significantly impact the energy sector.”

As the world grapples with the challenges of climate change and the need for sustainable energy solutions, innovations like these are crucial. The research conducted by Kaiwen Fan and his team at Shenyang Jianzhu University represents a significant step forward in the quest for green, low-carbon initiatives. By harnessing the power of functional fillers and thermoelectric properties, we can pave the way for a more energy-efficient and sustainable future.