In the quest to build more durable and energy-efficient structures, researchers have made a significant breakthrough that could reshape the construction landscape, particularly in challenging environments. A recent study published in the journal *Materials Research Express* (translated as “Materials Research Express”) has unveiled how silica fume can dramatically enhance the durability of polystyrene particle (EPS) concrete, a lightweight material with promising thermal insulation properties.

EPS concrete has long been recognized for its potential in building energy conservation and specialized structures. However, its susceptibility to corrosive conditions, such as those found in saline-alkali soils and marine environments, has limited its widespread adoption. Enter Zhouping Yu, a researcher from the College of Architecture and Environmental Engineering at Shaoxing Institute of Technology in China, who has been exploring ways to bolster the resilience of EPS concrete.

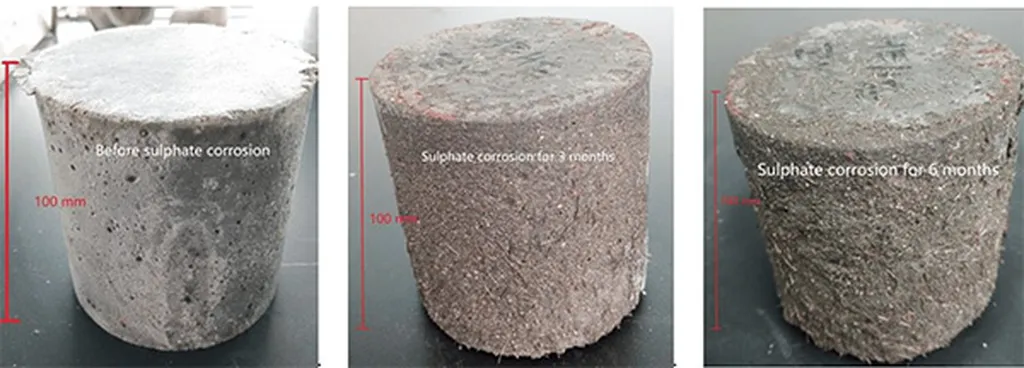

Yu’s study systematically investigates the role of silica fume (SF) in improving the resistance of EPS concrete to sulfate attack and chloride ion penetration. The findings are nothing short of remarkable. By adding SF, the researchers observed a significant improvement in both sulfate resistance and chloride permeability in EPS concrete. The optimal performance was achieved at a 10% SF dosage, where the EPS concrete exhibited a compressive strength retention rate 149.5% higher than that of the control group after 360 sulfate wet–dry cycles. Additionally, the mass loss rate was 67.6% lower, and the chloride migration coefficient decreased by 89.6%, reaching an ‘extremely low’ performance level.

“This study provides a theoretical foundation for the development and application of highly durable lightweight concrete in demanding environments such as marine engineering and saline-alkali regions,” Yu explained. The micromechanical analysis revealed that silica fume optimizes the microstructure through a synergistic mechanism involving physical filling, chemical inhibition, and interfacial strengthening. This combined effect consumes the reactants responsible for the formation of expansive corrosion products and significantly enhances the density and mechanical performance of the interfacial transition zone.

The implications of this research are profound for the construction industry, particularly in the energy sector. As the world increasingly turns to sustainable and energy-efficient building materials, the enhanced durability of EPS concrete could open up new avenues for its use in offshore wind farms, coastal infrastructure, and other challenging environments. The ability to withstand corrosive conditions without compromising on thermal insulation properties could make EPS concrete a game-changer in the quest for more resilient and energy-efficient structures.

Yu’s work not only sheds light on the potential of silica fume in improving the durability of EPS concrete but also paves the way for future research in this area. As the construction industry continues to evolve, the need for innovative solutions that can withstand the test of time and the elements becomes ever more critical. This study is a significant step in that direction, offering a glimpse into the future of construction materials and their role in building a more sustainable world.

In the words of Yu, “This research is just the beginning. There is still much to explore in terms of optimizing the performance of EPS concrete and other lightweight materials. But the potential is there, and the possibilities are exciting.” As the industry looks to the future, the insights gained from this study will undoubtedly play a crucial role in shaping the next generation of construction materials.