In a breakthrough that could reshape the energy sector, researchers have developed a novel aluminum alloy tailored specifically for additive manufacturing, promising stronger, more reliable components for high-performance applications. The study, led by Dr. Da Guo from University College London’s Mechanical Engineering department and the Research Complex at Harwell, introduces an Al–Ni–Ce–Mn–Fe alloy that significantly outperforms conventional materials in directed energy deposition (DED) processes.

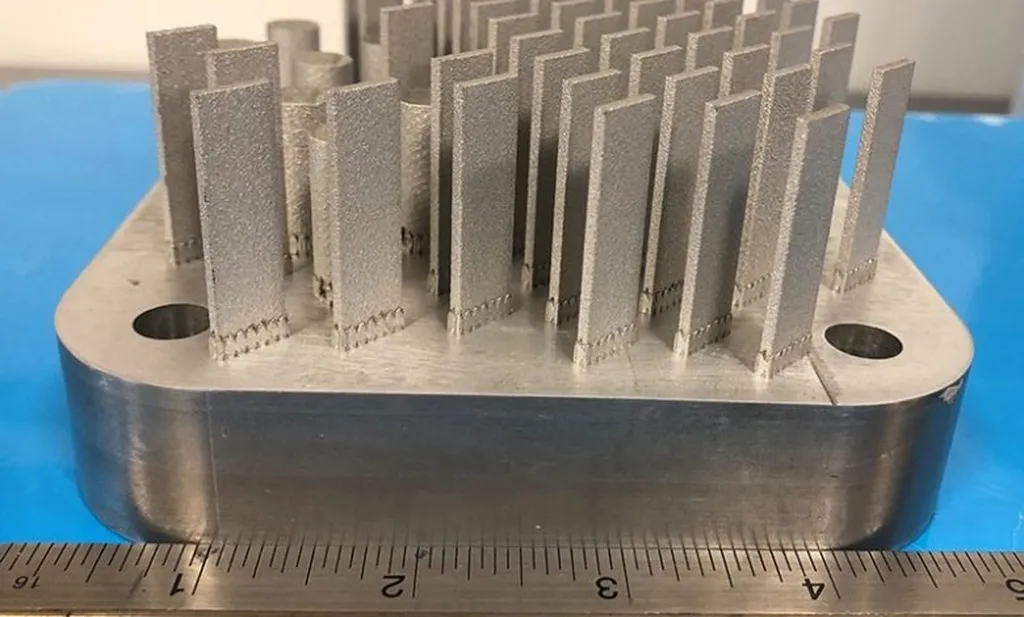

DED additive manufacturing is a game-changer for industries like energy, transport, and biomedical, allowing for the creation of complex, near-net-shaped components. However, its broader adoption has been hindered by the scarcity of alloys that can be reliably manufactured without imperfections, which in turn limits mechanical properties. Dr. Guo’s research addresses this challenge head-on.

“The key to our success lies in the ultra-fine microstructure and uniform distribution of intermetallics in our alloy,” explains Dr. Guo. “This results in low residual stress and superior mechanical properties, making it an ideal candidate for demanding engineering applications.”

The team achieved a 70% increase in yield strength and a 50% boost in ultimate tensile strength compared to the widely used DED AlSi10Mg alloy, all in the as-built state. This remarkable performance is attributed to the alloy’s unique composition and the rapid cooling and complex thermal conditions inherent in DED processes.

To gain deeper insights into the thermal-related behavior during DED, the researchers developed a novel multimodal characterization methodology. This approach combines in situ X-ray imaging, X-ray diffraction, and infrared imaging, enabling real-time quantification of phase evolution, temperature distribution, and stress accumulation.

“This correlative approach provides a mechanism-based guide for alloy design, which is crucial for advancing additive manufacturing technologies,” says Dr. Guo. The insights gained from this study could inform the development of next-generation materials tailored for specific AM conditions, paving the way for more efficient and reliable manufacturing processes.

The implications for the energy sector are substantial. The ability to produce stronger, more durable components on-demand could revolutionize energy production, storage, and distribution systems. From wind turbines to nuclear reactors, the potential applications are vast and varied.

The research was recently published in the International Journal of Extreme Manufacturing, which translates to the English as “International Journal of Extreme Manufacturing.” This study not only advances our understanding of additive manufacturing but also opens up new possibilities for material design and engineering. As Dr. Guo and his team continue to push the boundaries of what’s possible, the future of manufacturing looks brighter than ever.