In a significant stride toward sustainable materials, researchers have developed novel biobased polymers derived from lignin, a promising yet underutilized component of biomass. The study, led by Joanna Michalska-Walkowiak from the Institut Parisien De Chimie Moléculaire (IPCM) at Sorbonne Université in Paris, France, opens new avenues for green polymerization processes with potential commercial impacts, particularly in the energy sector.

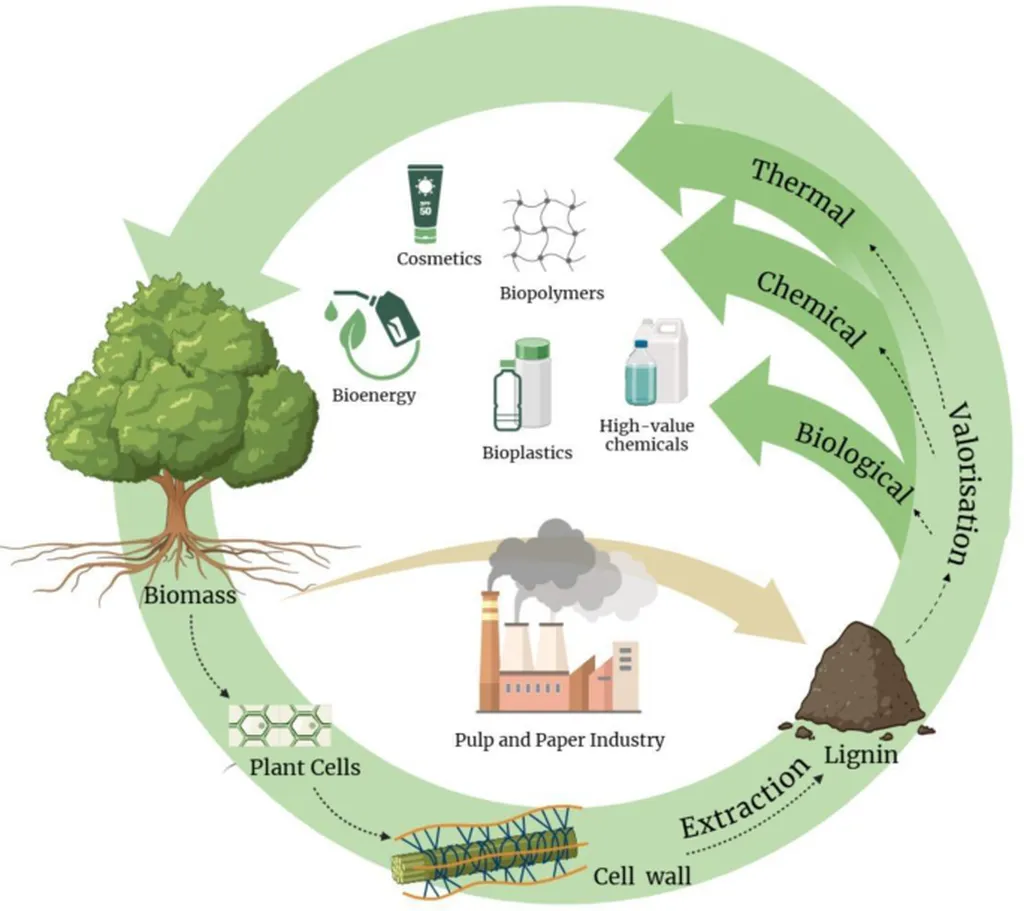

Lignin, a complex organic polymer found in the cell walls of plants, is often discarded as a byproduct in the paper and biofuel industries. However, Michalska-Walkowiak and her team have harnessed lignin’s potential by converting its oxidative degradation products—p-hydroxybenzaldehyde (H), vanillin (V), and syringaldehyde (S)—into radically polymerizable styrenic monomers. These monomers were then polymerized using two distinct methods: free radical polymerization in a green solvent, ethyl lactate, and emulsion polymerization using a biosourced surfactant.

The resulting polymers exhibit high thermal stability and tunable glass transition temperatures (Tg) ranging from 40°C to 110°C, depending on the monomer used. This tunability is crucial for various applications, including coatings, adhesives, and composite materials in the energy sector.

“Our approach not only utilizes a renewable resource but also employs green solvents and surfactants, making the entire process more sustainable,” Michalska-Walkowiak explained. The use of ethyl lactate, a biodegradable and non-toxic solvent, and a biosourced surfactant further enhances the eco-friendliness of the polymerization process.

The study, published in *Macromolecular Materials and Engineering* (translated to English as “Macromolecular Materials and Engineering”), highlights the potential for these biobased polymers to replace traditional petroleum-based materials. The energy sector, in particular, could benefit from these sustainable alternatives, which could be used in the production of insulating materials, membranes for fuel cells, and other high-performance applications.

The research also underscores the importance of developing green polymerization techniques. As the world shifts toward more sustainable practices, the ability to create high-performance materials from renewable resources becomes increasingly valuable. “This work is a step toward a more circular economy, where waste products like lignin are transformed into valuable materials,” Michalska-Walkowiak added.

The implications of this research extend beyond the energy sector. The tunable properties of the polymers make them suitable for a wide range of applications, from packaging to biomedical materials. As the technology matures, it could revolutionize the way we think about polymer production and waste utilization.

In conclusion, Michalska-Walkowiak’s work represents a significant advancement in the field of sustainable materials. By leveraging the potential of lignin and employing green polymerization techniques, the research paves the way for a more sustainable future. As the energy sector and other industries continue to seek eco-friendly solutions, these biobased polymers could play a pivotal role in shaping the materials of tomorrow.