In the ever-evolving world of aerospace composites, a new contender has emerged, promising to challenge the conventional laminates that have long dominated the industry. Double–Double (DD) laminates, with their unique design and manufacturing opportunities, are stepping into the spotlight. However, as with any innovative technology, there are nuances to understand, particularly when it comes to process-induced distortions (PID) like warpage.

Erik Kappel, a researcher at the German Aerospace Center (DLR), Institute of Lightweight Systems in Braunschweig, Germany, has been delving into the intricacies of DD laminates. His recent study, published in the open-access journal ‘Composites Part C: Open Access’ (translated as ‘Composites Part C: Open Access’), sheds light on why some DD laminates exhibit warpage and twist after a typical 180°C curing process, while others remain remarkably flat.

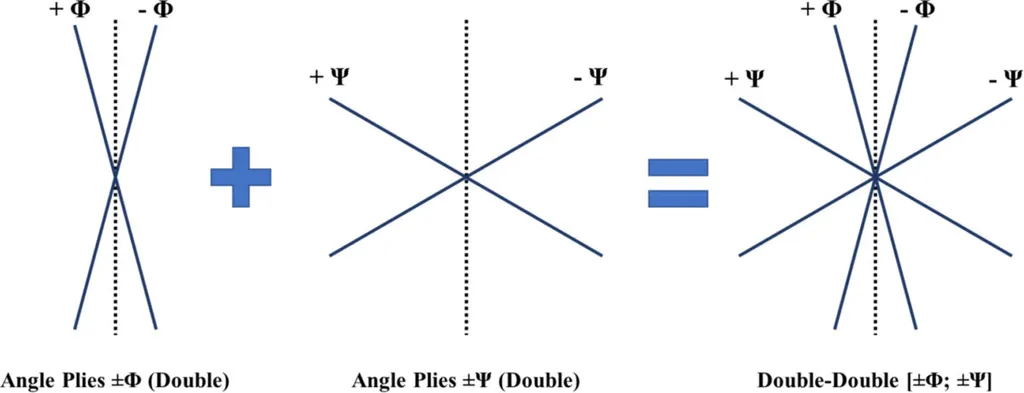

DD laminates are intriguing because they offer a mechanical behavior akin to orthotropic laminates, despite their asymmetric ply-stacking sequences. This phenomenon, known as ‘homogenization’, opens up new avenues for design and manufacturing. However, the topic of PID has been somewhat overlooked in the context of DD laminates, until now.

Kappel’s research provides practical guidance for selecting building-block stacking sequences that induce minimal warpage. “Understanding the root causes of warpage in DD laminates is crucial for their successful implementation in aerospace applications,” Kappel explains. “Our findings can help engineers make informed decisions during the design and manufacturing processes, ultimately leading to more efficient and reliable composite parts.”

The implications of this research extend beyond the aerospace industry. As the world shifts towards renewable energy sources, the demand for lightweight, high-strength materials in wind turbines and other energy sector applications is on the rise. DD laminates, with their unique properties and reduced propensity for warpage, could play a significant role in meeting these demands.

Moreover, the insights gained from Kappel’s study could pave the way for further advancements in composite design and manufacturing. As the industry continues to evolve, understanding and mitigating PID will be key to unlocking the full potential of innovative laminate technologies like DD laminates.

In the words of Kappel, “This research is just the beginning. As we continue to explore the capabilities of DD laminates, we are opening up new possibilities for the future of composite materials in various industries, including the energy sector.” With such promising prospects on the horizon, the future of DD laminates is certainly one to watch.