In the relentless pursuit of enhancing oil recovery and optimizing water shutoff operations, researchers have made a significant stride by introducing a novel nanocomposite that promises to revolutionize polymer gel systems. Heyder Mhohamdi, from the Department of Computers Techniques Engineering at The Islamic University, has led a study that could redefine the boundaries of conformance control in the energy sector.

The challenge of gel instability and poor performance under harsh reservoir conditions has long plagued the industry. Traditional polymer-based systems, while effective to some extent, often fall short in extreme environments. Mhohamdi and his team have addressed this issue head-on by developing Fe₃O₄@Saponin/Ni nanocomposites, which serve as synergistic reinforcing agents within a standard HPAM/Cr(III) acetate gel system.

What sets this research apart is the innovative incorporation of Nickel ions into the saponin-functionalized magnetite lattice. This unique structure forms thermally durable Ni–O–Fe bonds and additional coordination sites, significantly enhancing the gel’s resistance to thermal degradation and syneresis. “The formation of these bonds is a game-changer,” Mhohamdi explains. “It provides a level of thermal stability and mechanical resilience that we haven’t seen before in polymer gel systems.”

The synthesis process involves the sequential functionalization of Fe₃O₄ nanoparticles to ensure optimal dispersion and secondary crosslinking efficiency. Comprehensive characterization using FT-IR, TGA, SEM, and DLS, followed by rigorous testing of gelation kinetics, dispersion stability, rheology, syneresis resistance, and core flooding performance under reservoir-mimicking conditions, has yielded promising results.

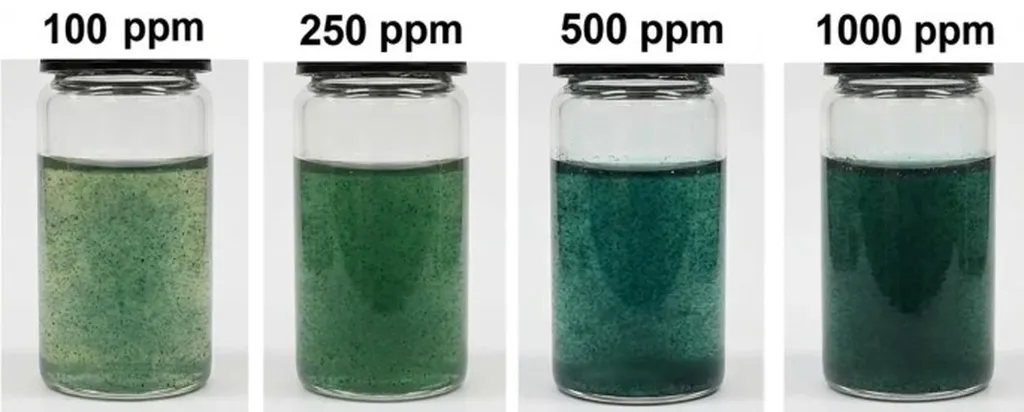

The nanocomposites improved thermal stability, ensured uniform nanoparticle size (20–50 nm), and promoted stable dispersion up to 500 ppm. The addition of these nanocomposites accelerated gelation rates at optimal concentrations (≤ 250 ppm), enhanced storage modulus, and dramatically reduced syneresis, exhibiting only 12% weight loss after two months at 110°C and 3000 psi. Core flooding tests confirmed the superior plugging efficiency, higher resistance factors, and long-term durability of the nanocomposite-reinforced gels compared to conventional formulations.

The commercial implications for the energy sector are substantial. Enhanced oil recovery (EOR) and water shutoff operations are critical for maximizing production and minimizing costs. The introduction of these nanocomposites could lead to more efficient and cost-effective solutions, particularly in challenging reservoir conditions. “This technology has the potential to transform the way we approach conformance control,” Mhohamdi states. “It offers a robust, multifunctional platform that can withstand the harshest environments, ensuring sustained performance and durability.”

Published in the journal Discover Nano (translated to English as “Exploring Nano”), this research opens new avenues for innovation in the field of enhanced oil recovery. As the energy sector continues to evolve, the development of advanced materials like these nanocomposites will play a pivotal role in shaping the future of conformance control. The findings not only address current limitations but also pave the way for further advancements, promising a more efficient and sustainable approach to oil and gas production.