In the relentless pursuit of materials that can withstand the harshest conditions, researchers have made a significant stride in enhancing the oxidation resistance of zirconium diboride (ZrB₂) composites. This breakthrough, published in the *Journal of Advanced Materials in Engineering* (translated from Persian as “Journal of Advanced Materials in Engineering”), holds promising implications for industries such as aerospace and energy, where materials are pushed to their limits.

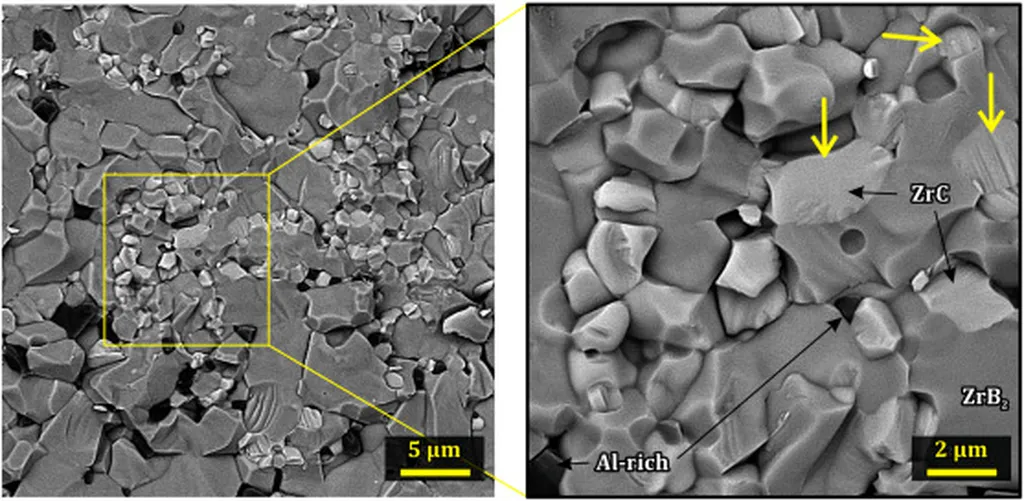

ZrB₂ composites are already renowned for their high melting points and exceptional thermal properties, making them ideal for applications in extreme environments. However, their susceptibility to oxidation has been a persistent challenge. Enter Zohre Balak, a researcher from the Department of Materials Science and Engineering at Ahvaz Islamic Azad University in Iran, who led a study investigating the effect of adding nano carbon black and silicon carbide (SiC) on the oxidation resistance of these composites.

The study, which involved preparing five different samples with varying compositions, revealed that the addition of nano carbon black and SiC significantly improved the oxidation resistance of ZrB₂ composites. “The addition of 10 vol% nano carbon black reduced the oxidation layer thickness from 129 ± 5 µm in pure ZrB₂ to 110 ± 6 µm,” Balak explained. This might seem like a modest improvement, but in the world of materials science, even small gains can translate into significant enhancements in performance and longevity.

The most striking result came from the ZrB₂-30 vol% SiC composite containing 10 vol% nano carbon black, which exhibited the lowest oxidation layer thickness (55 ± 3 µm) and the highest oxidation resistance. This finding opens up new avenues for developing materials that can operate efficiently in high-temperature environments, such as in gas turbines, jet engines, and other energy sector applications.

The implications of this research are far-reaching. Improved oxidation resistance means longer-lasting materials, reduced maintenance costs, and enhanced safety. As the energy sector continues to demand materials that can withstand increasingly harsh conditions, innovations like this are crucial. “This study not only advances our understanding of ZrB₂ composites but also paves the way for their broader application in industries where high-temperature stability is paramount,” Balak noted.

The study’s findings, published in the *Journal of Advanced Materials in Engineering*, underscore the importance of ongoing research in materials science. As we strive to push the boundaries of what’s possible, such breakthroughs will be instrumental in shaping the future of energy and aerospace technologies. The journey towards materials that can withstand the extremes of our world is ongoing, and this research is a significant step forward.