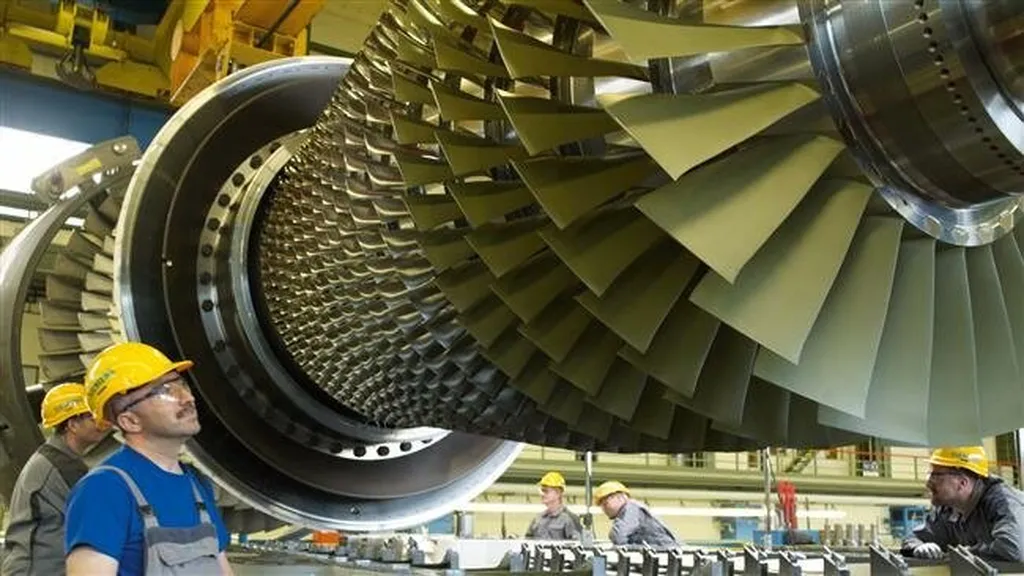

In the high-stakes world of industrial gas turbines, where reliability and efficiency are paramount, a recent study has shed new light on optimizing the welding processes for critical components. Mohammad Reza Sheikhmohseni, from the School of Metallurgy and Materials Engineering at Iran University of Science and Technology (IUST), Tehran, Iran, led a comprehensive analysis of heat input and filler metal effects on the microstructure and mechanical properties of cobalt-based FSX-414 superalloy, a material widely used in the fabrication of first-row stationary vanes in Frame-9 industrial gas turbines.

The study, published in the Journal of Advanced Materials in Engineering (translated to English as “Journal of Advanced Materials in Engineering”), focused on enhancing the durability, mechanical strength, and performance stability of FSX-414 components at elevated temperatures. This is crucial for the energy sector, as these components are subjected to severe conditions such as thermal fatigue, oxidation, and creep during prolonged service, which can significantly reduce their service life and compromise the reliability of the turbine.

Sheikhmohseni and his team employed the Gas Tungsten Arc Welding (GTAW) process, varying welding currents and using different filler metals to evaluate their effects on the microstructure and mechanical properties of the superalloy. “We found that a welding current of 60 A provided the most favorable weld quality,” Sheikhmohseni explained. “At this optimized current, we tested four different filler metals—FSX-414, HS25, HS188, and Mar-M918—to see how they influenced the mechanical behavior of the welded specimens.”

The results were revealing. For most welded specimens, failure occurred in the base metal rather than in the weld zone, confirming the adequacy of the welding procedure. However, in the specimen welded with HS188 filler metal, fracture initiated within the weld metal. Detailed analysis showed local segregation of chromium and tungsten in interdendritic regions and the transformation of primary MC carbides into M23C6 carbides, which promoted the formation of brittle phases and facilitated crack initiation.

The study also found that the filler metal Mar-M918 provided the highest tensile strength and toughness at both room temperature and 650°C, making it a promising candidate for enhancing the performance of FSX-414 components in high-temperature applications. “Our findings suggest that by carefully selecting the filler metal and optimizing the welding parameters, we can significantly improve the mechanical properties and durability of these critical components,” Sheikhmohseni noted.

The implications for the energy sector are substantial. As gas turbines continue to play a vital role in power generation, the ability to enhance the reliability and efficiency of these machines is of paramount importance. This research provides valuable insights into optimizing welding processes for FSX-414 superalloys, paving the way for more robust and long-lasting components in industrial gas turbines.

Moreover, the study highlights the importance of microstructural characterization and fracture analysis in understanding the mechanical behavior of welded specimens. By delving deep into the microstructure, researchers can identify potential weaknesses and develop strategies to mitigate them, ultimately leading to more resilient and high-performing materials.

As the energy sector continues to evolve, the demand for advanced materials and innovative welding techniques will only grow. This research serves as a testament to the power of materials science and engineering in driving progress and shaping the future of energy production. With further advancements in this field, we can expect to see even more significant improvements in the performance and reliability of industrial gas turbines, ultimately benefiting the broader energy landscape.