In the relentless pursuit of enhancing the durability and performance of industrial components, a team of researchers led by Faezeh Badiee from the Faculty of Applied Sciences at Malek Ashtar University of Technology in Shahin Shahr, Isfahan, has made a significant breakthrough. Their study, published in the Journal of Advanced Materials in Engineering—known in English as the Journal of Advanced Materials in Engineering—focuses on improving the wear and corrosion resistance of electroless Ni-P/Ni-B coatings by incorporating ceria nanoparticles through a sol-enhanced method.

Wear and corrosion are perennial challenges that significantly reduce the service life and efficiency of industrial components, particularly in harsh environments like those found in the energy sector. Badiee and her team aimed to address these issues by developing a more robust coating that could withstand the rigors of such environments.

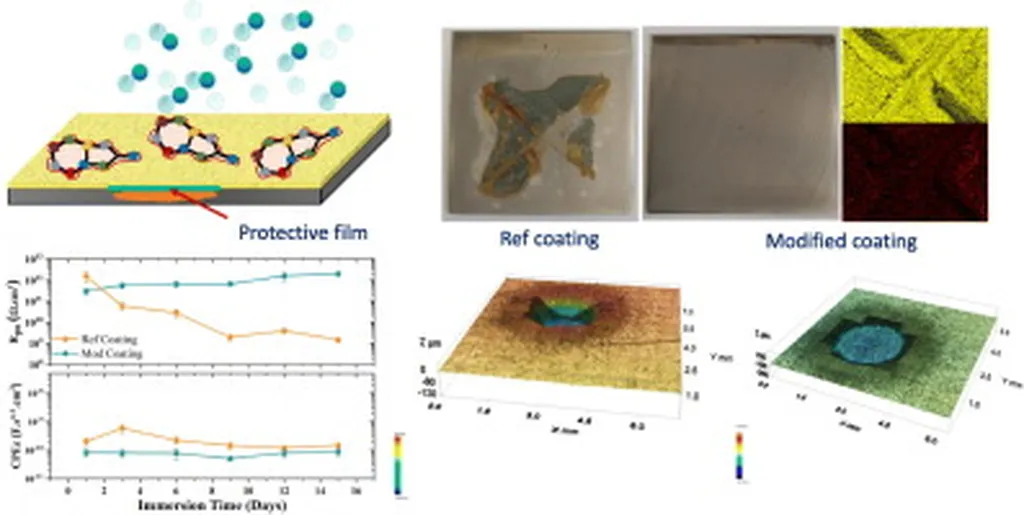

The researchers achieved a uniform distribution of ceria nanoparticles by introducing ceria sol derived from an alkoxide precursor into the Ni-B electroless bath. This innovation led to the formation of a relatively dense Ni-B coating with excellent surface quality and minimal surface cracks. “The use of ceria sol improved the uniformity of the distribution of reinforcing particles, which is crucial for enhancing the mechanical and tribological properties of the coating,” Badiee explained.

Characterization of the coating was performed using various techniques, including XRD and FE-SEM, DLS, potentiodynamic polarization tests, and pin-on-disk wear tests. The results were promising. The polarization curve indicated that the CeO2-containing coating exhibited a more stable and slower rate of corrosion compared to the substrate. This improvement was attributed to the formation of a protective layer and increased surface chemical stability.

Perhaps most notably, the application of the Ni-P/Ni-B-CeO2 coating on an aluminum substrate resulted in a 21% reduction in the friction coefficient and a 70% reduction in the specific wear rate compared to the uncoated substrate. These findings suggest that the enhanced coating could significantly extend the lifespan of industrial components, reducing maintenance costs and downtime.

The commercial implications for the energy sector are substantial. Components used in power generation, oil and gas extraction, and renewable energy systems often operate under extreme conditions, where wear and corrosion can lead to frequent failures and high replacement costs. The development of more durable coatings could revolutionize the industry, making operations more efficient and cost-effective.

Badiee’s research not only highlights the potential of sol-enhanced methods in improving coating properties but also opens new avenues for further exploration. Future studies could focus on optimizing the concentration of ceria nanoparticles and exploring other reinforcing particles to achieve even greater improvements in wear and corrosion resistance.

As the energy sector continues to evolve, the demand for advanced materials that can withstand harsh operating conditions will only grow. Badiee’s work represents a significant step forward in meeting this demand, offering a glimpse into a future where industrial components are more resilient, reliable, and cost-effective.