In the quest to optimize steel production for the automotive industry, researchers have turned to advanced testing methods to better understand the behavior of dual-phase steels under hot rolling conditions. A recent study published in the *Journal of Advanced Materials in Engineering* (or, in English, the Journal of Advanced Materials in Engineering) sheds light on the critical temperatures of DP600 steel, a material widely used for its exceptional strength and formability. The research, led by Amir Gheysarian from the Department of Materials Engineering at Isfahan University of Technology in Iran, could have significant implications for the energy sector and beyond.

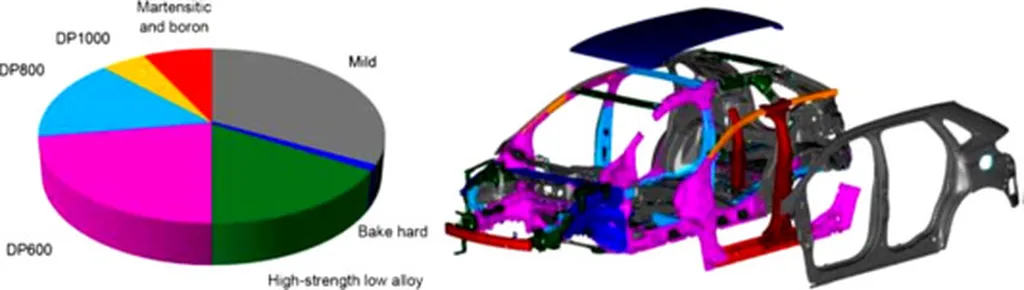

Dual-phase steels, particularly DP600, are prized for their unique combination of high strength and good formability, making them ideal for automotive applications. However, producing these steels with consistent mechanical properties requires a deep understanding of their hot deformation behavior. To this end, Gheysarian and his team employed the hot torsion test, a method that simulates industrial hot rolling conditions with remarkable accuracy.

“The hot torsion test allows us to mimic the complex deformation processes that occur during hot rolling,” Gheysarian explained. “By doing so, we can determine the critical temperatures that are essential for designing optimal rolling schedules.”

The researchers conducted two different rolling schedules: the average test and the actual test. The average test yielded critical temperatures of 910°C for the no-recrystallization temperature (Tnr), 790°C for the starting temperature of austenite-to-ferrite transformation (Ar3), and 760°C for the finishing temperature of ferrite transformation (Ar1). In contrast, the actual test, which more closely simulates real rolling conditions, produced slightly higher temperatures: 931°C for Tnr, 825°C for Ar3, and 765°C for Ar1.

These differences highlight the importance of considering non-equilibrium conditions in the hot rolling process. “The values obtained from the actual test are more reliable for designing an optimal rolling schedule,” Gheysarian noted. “This can lead to the production of dual-phase steel with the desired tensile strength, ultimately benefiting the automotive industry and other sectors that rely on high-performance steels.”

The findings of this study could have far-reaching implications for the energy sector, where the demand for high-strength, lightweight materials is growing. By optimizing the production of dual-phase steels, manufacturers can reduce material waste, improve energy efficiency, and enhance the overall performance of their products.

Moreover, the research underscores the importance of advanced testing methods in materials science. As Gheysarian and his team have demonstrated, the hot torsion test is a valuable tool for simulating industrial processes and gaining insights into the behavior of complex materials.

In the broader context, this study contributes to the ongoing efforts to improve the sustainability and efficiency of steel production. By refining the hot rolling process, manufacturers can minimize energy consumption and reduce their environmental footprint, aligning with the global push towards more sustainable industrial practices.

As the demand for high-performance materials continues to grow, research like this will be crucial in driving innovation and shaping the future of the materials science field. With the insights gained from this study, engineers and manufacturers can take a significant step forward in optimizing the production of dual-phase steels, paving the way for advancements in various industries, including the energy sector.