In the quest to optimize oil recovery from clay-rich reservoirs, researchers have made a significant stride by developing a novel nanocomposite that mitigates fines migration during low-salinity waterflooding. This breakthrough, published in the journal *Discover Nano* (translated as “Exploring Nano”), offers a promising solution to a longstanding challenge in the energy sector.

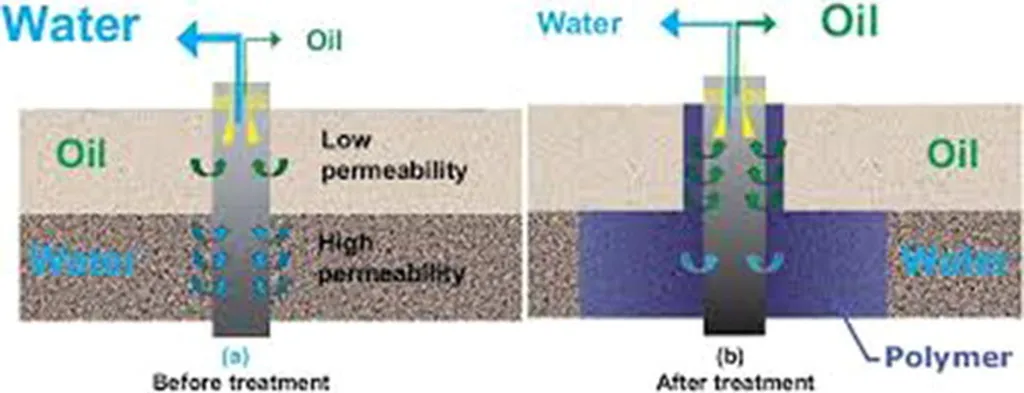

Fines migration, the movement of small particles within reservoir rocks, can severely impair permeability and reduce oil production. Traditional high-salinity waterflooding methods prevent this issue but are environmentally and economically costly. Low-salinity waterflooding, while more sustainable, often exacerbates fines migration due to the expansion of the electrostatic double layer, which destabilizes clay-mineral adhesion.

Enter Kassem A. L. Attabi, a researcher from the Department of Computers Techniques Engineering at the College of Technical Engineering, The Islamic University. Attabi and his team have developed a Fe₃O₄@saponin/Cu nanocomposite that effectively suppresses fines release and permeability loss during low-salinity waterflooding. “Our nanocomposite shifts the mineral surface charge toward neutral or slightly positive values, reducing electrostatic repulsion between fines and the pore matrix,” Attabi explains. This innovative approach combines electrostatic neutralization, steric stabilization, and magnetic/coordination bridging to anchor fines to pore surfaces without plugging.

The team’s laboratory-scale experiments demonstrated striking results. Untreated low-salinity water caused a catastrophic permeability loss of 69.9% and tripled injection pressure. However, adding just 500 ppm of the nanocomposite reduced impairment to a mere 4.1%, comparable to high-salinity conditions without treatment. “This mitigation mechanism involves a synergistic combination of electrostatic neutralization, steric stabilization from the saponin corona, and magnetic/coordination bridging,” Attabi elaborates.

The implications for the energy sector are substantial. By enabling low-salinity flooding while suppressing fines migration, this nanocomposite provides a practical and sustainable alternative to high-salinity injection. This could lead to enhanced oil recovery, reduced environmental impact, and significant cost savings.

As the energy industry continues to seek more efficient and eco-friendly methods for oil recovery, this research paves the way for future developments. The Fe₃O₄@saponin/Cu nanocomposite not only addresses the critical issue of fines migration but also aligns with the growing demand for sustainable practices in the energy sector. With further research and field-scale testing, this innovation could revolutionize oil recovery processes, making them more efficient and environmentally friendly.

In the words of Attabi, “This is just the beginning. The potential applications of our nanocomposite extend beyond oil recovery, offering a glimpse into a future where advanced materials play a pivotal role in sustainable energy solutions.” As the industry looks to the horizon, this research stands as a beacon of progress, illuminating the path toward a more efficient and sustainable energy future.