In the quest for more durable and cost-effective materials, researchers have turned their attention to cemented carbides, a critical component in various industrial applications, particularly in the energy sector. A recent study published in *Materials Research* (or *Pesquisa em Materiais* in Portuguese) has shed new light on the electrochemical corrosion behavior of WC-Ni-Al and WC-Co cemented carbides, potentially paving the way for more resilient and economical alternatives in harsh environments.

The study, led by Flávio Amaury de Freitas Matos, a researcher affiliated with a prominent institution, compared the corrosion resistance of WC-NiAl cemented carbide with the conventional WC-Co cemented carbide. The findings are promising, especially for industries that rely heavily on materials that can withstand corrosive environments.

Cemented carbides are widely used in drilling, mining, and other high-wear applications due to their exceptional mechanical properties. However, the high cost and toxicity of cobalt, a common binder in these materials, have driven the search for alternatives. The study’s focus on WC-NiAl cemented carbide offers a glimpse into a potential solution.

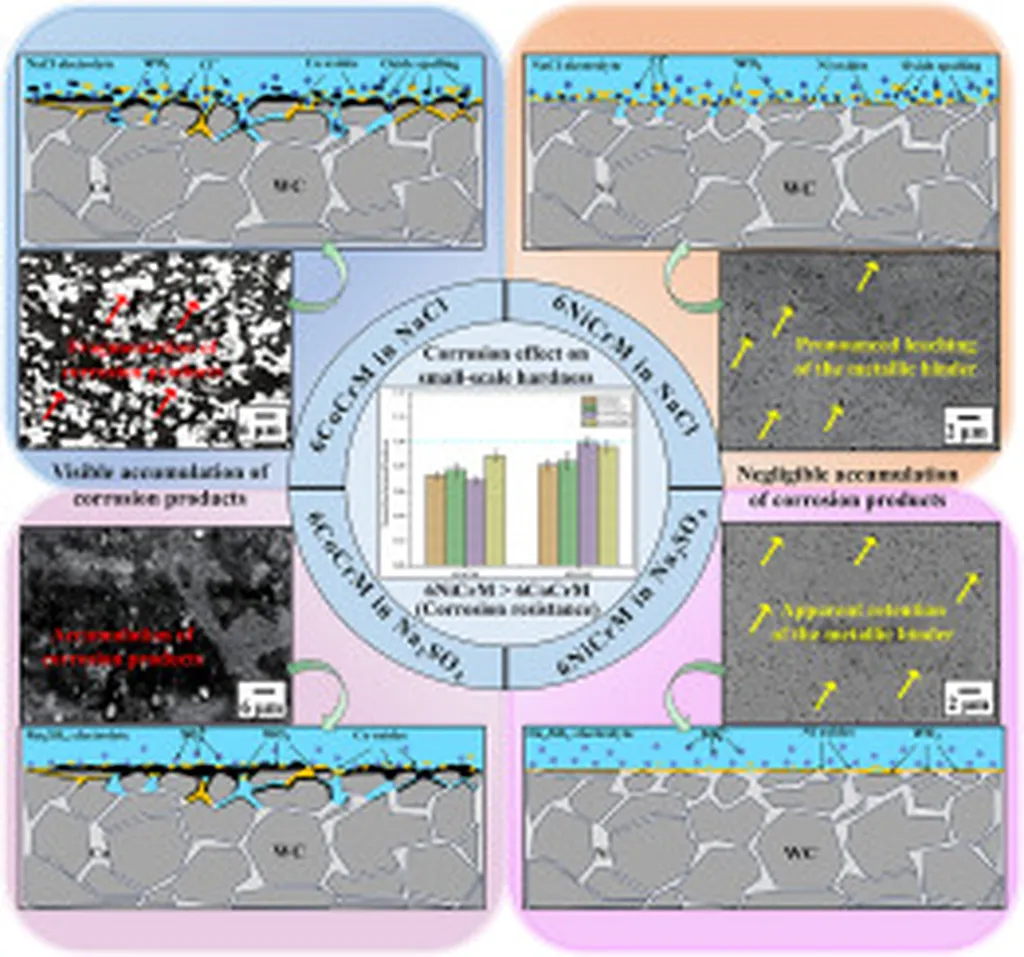

“Our research demonstrates that the WC-NiAl cemented carbide exhibits more noble potentials, lower current density values, and higher total impedance than the traditional WC-Co cemented carbide,” Matos explained. This means that the new material is more resistant to corrosion, a critical factor in extending the lifespan of components used in corrosive environments.

The electrochemical tests, including open circuit potential, linear potentiodynamic polarization, and electrochemical impedance spectroscopy (EIS), revealed that the sample with the nickel and aluminum binder outperformed the cobalt-bound sample. This superior performance could translate into significant cost savings and improved safety for industries that rely on these materials.

The implications for the energy sector are substantial. For instance, in offshore drilling and mining operations, where equipment is constantly exposed to corrosive elements, the use of more corrosion-resistant materials could lead to longer equipment lifespans and reduced maintenance costs. Additionally, the reduced toxicity of the new binder phase could contribute to safer working conditions and environmental benefits.

As the energy sector continues to push the boundaries of exploration and extraction, the demand for materials that can withstand extreme conditions will only grow. This research not only highlights the potential of WC-NiAl cemented carbides but also underscores the importance of ongoing innovation in materials science.

The study, published in *Materials Research*, serves as a testament to the ongoing efforts to improve the durability and cost-effectiveness of materials used in critical industries. As Matos and his team continue to explore the potential of these new materials, the energy sector can look forward to more resilient and economical solutions for its most challenging applications.