In the heart of South Korea, researchers at the Korea Advanced Institute of Science and Technology (KAIST) have made a breakthrough that could revolutionize humidity sensing technology, with significant implications for the energy sector. Vu Binh Nam, a lead author from the Manufacturing and Instrumentation Laboratory in the Department of Mechanical Engineering, and his team have developed a novel approach to fabricating transparent and flexible humidity sensors using copper oxide (CuOx) and a laser-induced reductive sintering process.

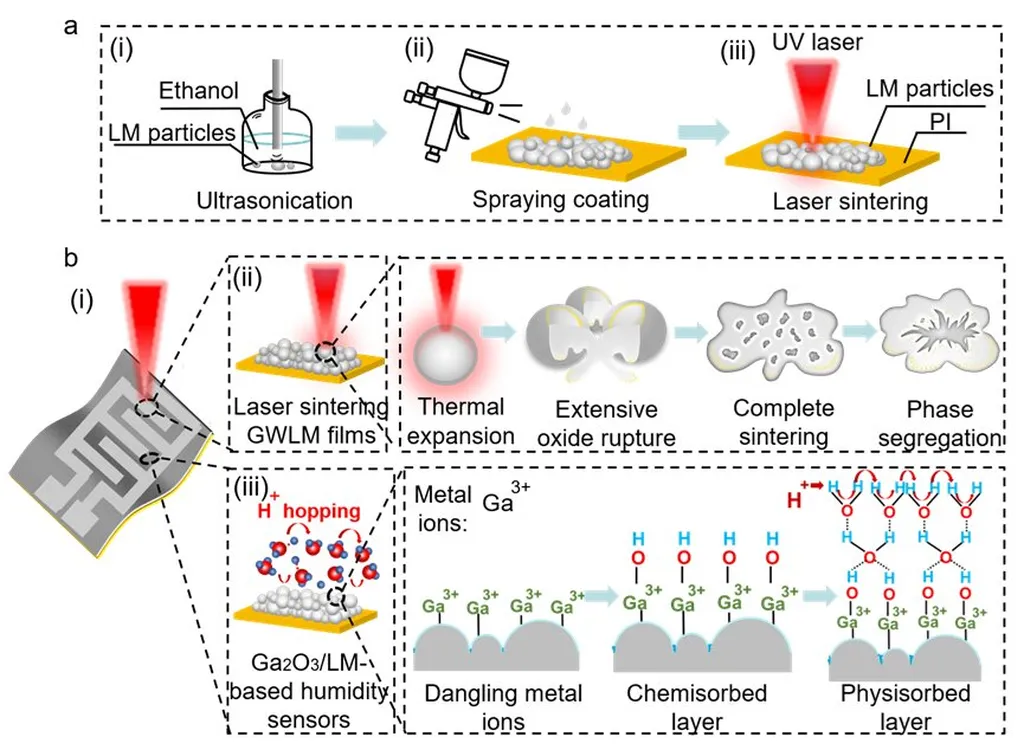

The innovation lies in the simplicity and efficiency of the fabrication process. By applying localized thermal energy to a CuOx nanoparticle thin film on a flexible polyethylene terephthalate (PET) substrate, the laser process simultaneously forms conductive copper electrodes and a semiconducting sensing channel within a single layer. This is achieved through direct and indirect reductive sintering at the CuOx/PET and Cu/CuOx interfaces, respectively.

“The beauty of this process is its simplicity and the fact that it can be done under ambient conditions,” Nam explains. “We’re able to create a highly sensitive, transparent, and flexible humidity sensor in a single step, which opens up numerous possibilities for practical applications.”

The sensors developed by Nam and his team exhibit remarkable properties. They operate reliably within a relative humidity range of 25‒80%, with high sensitivity (7.04 × 104) and rapid response and recovery times (0.35 s and 0.80 s). Moreover, they boast impressive optical transparency (96.1% at 550 nm) and mechanical flexibility, as confirmed by various bending and twisting tests.

The enhanced performance of these sensors can be attributed to the significant increase in Cu+ in the CuOx sensing channel, induced by the indirect reductive sintering process. This enhancement promotes water adsorption and proton conduction at the CuOx/water molecule interfaces under humid conditions.

The potential commercial impacts of this research are substantial, particularly for the energy sector. Accurate and efficient humidity sensing is crucial for various applications, including energy-efficient HVAC systems, humidity control in data centers, and monitoring environmental conditions in renewable energy facilities. The transparency and flexibility of these sensors make them ideal for integration into smart windows, wearable devices, and other innovative technologies.

As the world continues to demand more sophisticated and efficient energy solutions, the development of advanced sensing technologies becomes increasingly important. The work of Nam and his team, published in the journal ‘Applied Surface Science Advances’ (translated from the original title ‘Advances in Applied Surface Science’), represents a significant step forward in this field.

“This research not only advances our understanding of laser-induced reductive sintering but also paves the way for the development of next-generation humidity sensors,” Nam says. “We are excited to explore the potential applications of this technology and its impact on various industries.”

The study’s findings could inspire further research and development in the field of flexible and transparent electronics, ultimately contributing to the creation of more efficient and sustainable energy systems. As the world grapples with the challenges of climate change and energy demand, innovations like these offer a glimmer of hope and a path forward.